Connectors refer to components used to connect electrical components or electronic devices, which are an indispensable part of electronic circuits.Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons.

اتصل الآن

Our baohua business enterprise has mould engineers to make molds consistent with the patron's quantity demand and carry out green manufacturing. material kinds and weights can also be made consistent with patron requirements. with a view to comprehend the precision forging of flange merchandise, make the cloth utilization rate reach above 90%, and greatly save the cost.Similarly, our agency also has difficult machining, warmth remedy and completing, which can be brought below specific delivery situations in keeping with patron necessities, saving time and cost.

اتصل الآن

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, 4140, 4130 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-7000kg, forging needs to be completed through heating, pre-forging, forming and other processes.

اتصل الآن

As a mechanical part that stops or slows down the moving parts in the machine, the brake shell can be produced according to the materials required by customers in the production process. At present, our Baohua Company uses 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc., which are widely used. The processing of the brake shell needs to be completed by heating, pre-forging, forming, trimming and other processes. According to different weights, the forged products can be forged on different forging equipment units, and the weight of forged products can reach 6kg-500kg.

اتصل الآن

As a mechanical part that stops or slows down the moving parts in the machine, the brake shell can be produced according to the materials required by customers in the production process. At present, our Baohua Company uses 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc., which are widely used. The processing of the brake shell needs to be completed by heating, pre-forging, forming, trimming and other processes. According to different weights, the forged products can be forged on different forging equipment units, and the weight of forged products can reach 6kg-500kg.

اتصل الآن

There are no special requirements for the material of the supporting shaft. In the process of production, manufacturers mainly produce according to their actual availability. Basically follow the following principles:1. Select the materials for manufacturing the supporting shaft according to the use of the main parts. If it is used for support, it should be made of materials that can bear the support. If it is used for fixing, it is necessary to select materials that are convenient for welding the support shaft and the fixing point.2.

اتصل الآن

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 15kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.The Supporting Shaft Component Structure and bobbin collet shaft device of filament winding machine discloses a supporting shaft component structure and bobbin collet shaft device of filament winding machine.

اتصل الآن

Our company has ISO-9001 certificate, and the production of supporting shaft is integrally forged with a corresponding model of die forging hammer, with high efficiency and low cost. And various types of materials can be used, such as 42CrMo, 45#, 35CrMo, 4140, 4130, etc. After repeated heating pre-forging and die forging, the forging ratio is high and the durability is good. It is suitable for fitting installation of engineering machinery and wind power industry equipment.

اتصل الآن

The completed threaded flange we produce may be processed by using hot-die forging, difficult operating, warmth remedy and different approaches, thus growing the forging ratio and performance stability. Completed threaded flange can be similarly processed to acquire very last meeting conditions.The corporation uses a continuing rolling ring technique, which ends up in more solid product performance and greatly decreased weight and value financial savings.

اتصل الآن

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment, and is used for the connection between two equipment, such as reducing pipe flanges. There are holes in the flanges, and bolts make the two flanges closely connected. All connecting parts that are bolted around two planes and closed at the same time are generally called "flanges", such as the connection of ventilation pipes. Such parts can be called "flange parts".

اتصل الآن

Flange, additionally known as flange or flange. flange is a part of connecting shaft, which is used to connect pipe ends; it's also used for flanges at the inlet and outlet of device, and is used for the relationship among gadget, including decreasing pipe flanges. there are holes inside the flanges, and bolts make the two flanges closely connected. all connecting parts which are bolted round two planes and closed at the same time are usually known as "flanges", which includes the relationship of air flow pipes.

اتصل الآن

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment, and is used for the connection between two equipment, such as reducing pipe flanges. Flange connection or flange joint refers to the detachable connection of flange, gasket and bolt as a set of combined sealing structure.MATERIAL4130-75KHARDNESS207-237INNER DIAMETER52.71OUTSIDE DIAMETER504.95Our Baohua Company was founded in 1969.

اتصل الآن

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, 4140, 4130 and other materials. According to different weights, it can be forged on different forging equipment units, and the weight of the forged products can reach 6kg-5000kg, forging needs to be completed through heating, pre-forging, forming and other processes.Forging is a processing method that uses forging machinery to exert pressure on metal blank to make it produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes.

اتصل الآن

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment, and is used for the connection between two equipment, such as reducing pipe flanges. There are holes in the flanges, and bolts make the two flanges closely connected. All connecting parts that are bolted around two planes and closed at the same time are generally called "flanges", such as the connection of ventilation pipes. Such parts can be called "flange parts".

اتصل الآن

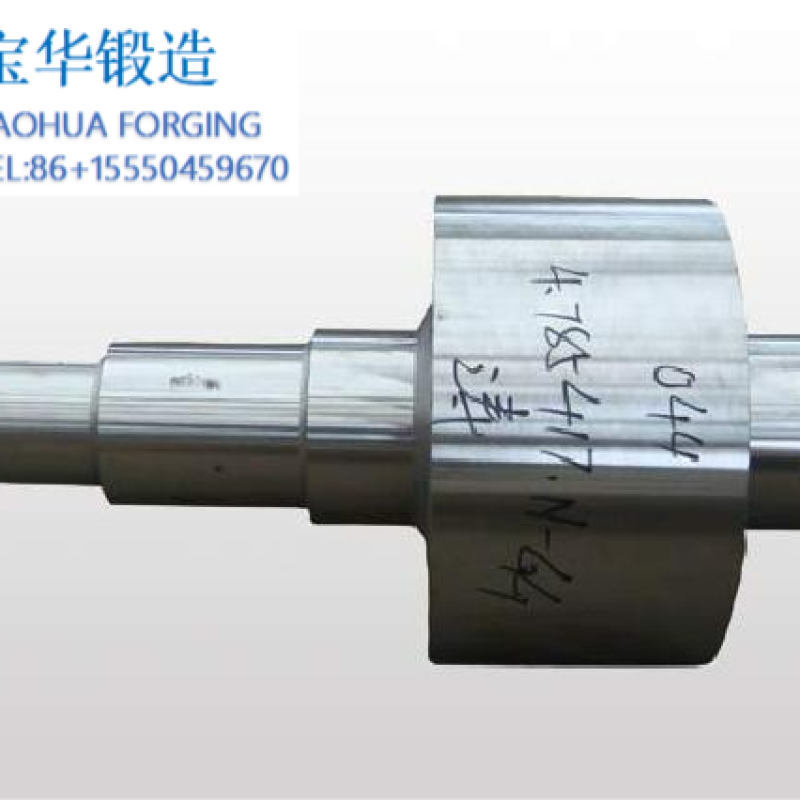

The driving shaft forgings produced by our company are mainly used in construction machinery industry, petroleum industry and wind power industry. The raw materials are hot rolled round steel or ingot recognized at home and abroad. According to customer's requirements, we can carry out hot forging and forming, and meet the requirements of ultrasonic testing (UT). Forging can improve product performance and save cost.

اتصل الآن

Our company employs a new seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower volume requirements and near-finish shapes to save on final tooling costs. All of our forgings can go through hot die forging, rough machining, heat treatment and other processes, and the forgings can be finished to reach the final assembly condition.

اتصل الآن

The middle shaft is a cylindrical object that passes through the middle of a bearing, wheel or gear, but a few of them are square. The middle shaft is a mechanical part that supports the rotating part and rotates with it to transmit motion, torque or bending moment. Generally, it is a metal round bar, and each section can have a different diameter. In the machine, the rotating parts are mounted on the shaft.The intermediate shaft forgings produced by our company are mainly used in equipment accessories of construction machinery industry, petroleum industry and wind power generation industry.

اتصل الآن

Our Baohua company has mold design engineers who can provide drawings according to customersIndependently designed and developed the mold, making the fixed shaft locking sleeve integrally forged, greatly saving materials, and improving the stability of the product. In addition, our company has the ability of finishing, which can cover multiple integrated processes such as forging, machining, heat treatment and finishing, and can finally achieve the delivery of finished products.

اتصل الآن

Selection of positioning datumThe machining sequence of the main surface of the gear shaft largely depends on the selection of the positioning datum. The structural characteristics of shaft parts and the position accuracy requirements of the main surface of the spindle determine that taking the axis as the positioning datum is the most ideal. This not only ensures the unity of the datum, but also makes the positioning datum coincide with the design datum. Generally, the outer circle is the coarse datum, and the sharp holes at both ends of the shaft are the fine datum.

اتصل الآن

For the forging and casting of screw tee, our Baohua Company mainly focuses on forging. Customers can make requests according to their own needs, and we will carry out forging production according to the drawings provided. Like simple and numerous products, our company's mold engineers improve the production speed and accuracy of products by building molds. For our enterprise itself, from the state-owned to the individual, it has gone through three generations of family management, and the equipment is constantly updated.

اتصل الآن

For the manufacturing of Crusher Long Hammer products, our agency is capable of independently design dies and forge according to product specifications. cloth type and weight can also be produced in line with client requirements.

اتصل الآن

As a mechanical part that stops or slows down the moving parts in the machine, the brake shell can be produced according to the materials required by customers in the production process. At present, our Baohua Company uses 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc., which are widely used. The processing of the brake shell needs to be completed by heating, pre-forging, forming, trimming and other processes. According to different weights, the forged products can be forged on different forging equipment units, and the weight of forged products can reach 6kg-500kg.

اتصل الآن

Our company is able to design dies independently and forge according to product specifications. Material type and weight can be made according to customer requirements. Our company can design the die according to the drawings provided by customers, thus realizing the precision forging, which makes the material utilization more than 90%, thus greatly saving the cost.In addition, our company also has rough machining, heat treatment and finish machining, a complete line process, and delivery according to customer requirements of different delivery status.

اتصل الآن

We have many years of certificates such as AIP Q, and we are also very skilled in producing related products such as bar heads.According to the model of this product, the die and forging are integrated, and mass production is executed. thereby decreasing prices and excessive performance. and our business enterprise can use various varieties of substances inclusive of: 4140, 35CrMo, 42CrMo, forty five#, 4130 and so forth.

اتصل الآن